Cutting Tools

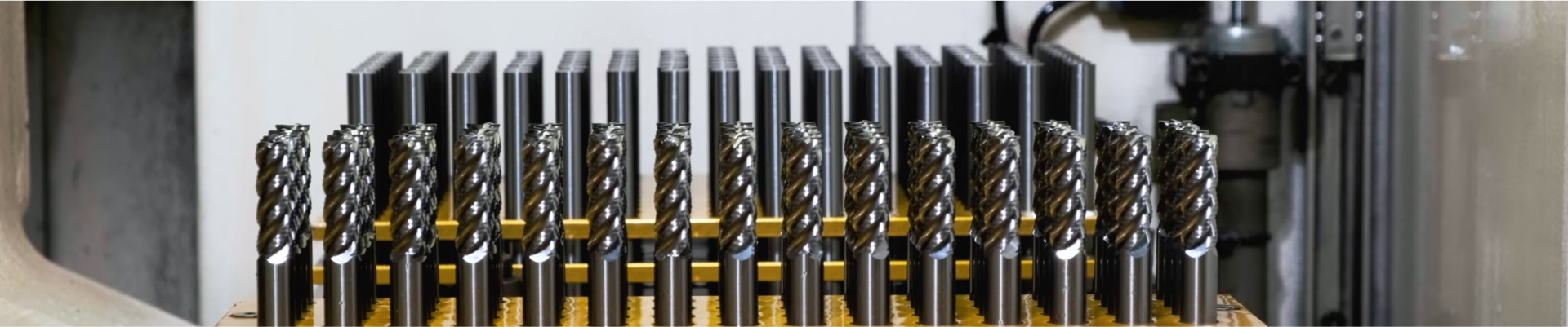

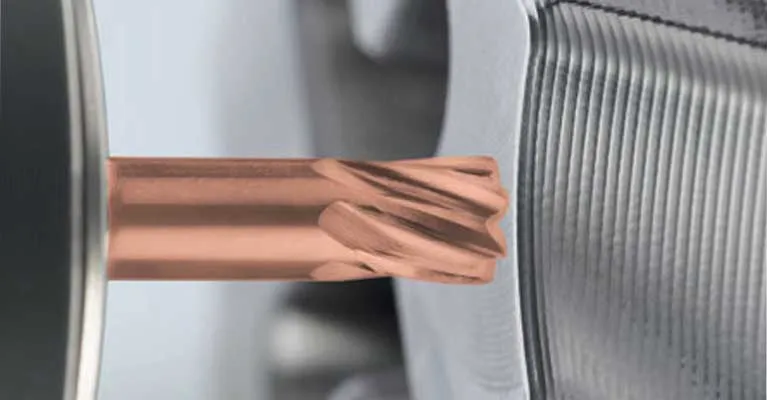

Synergy India empowers manufacturers with intelligent, high-precision Cutting Tools sourced from the most trusted OEMs around the globe. We design our solutions to achieve high productivity. As a leading Cutting Tools Supplier, our tools are made durable and cost-efficient. From carbide drills and endmills to advanced tool holding systems, we deliver Industrial Cutting Tools that meet the toughest machining challenges with consistency and reliability.

As a Cutting Tools Distributor, Synergy offers a wide range of solutions.

We partner with top brands and stand out as a trustworthy Industrial Cutting Tools Distributor to deliver a comprehensive range of cutting solutions:

LMT Tools

Synergy India is an LMT Tool Supplier and provides unmatched machining solutions as an integral part of bringing trustworthy, precise, and advanced solutions.

- Milling solutions: detachable and solid carbide mills for high-precision and high-performance machining.

- Drilling solutions: solid carbide drills for selective processes & mechanics.

- Threading: Ideal for tough materials with high-quality threads.

- Gear-rack cutting and reaming: A trusted backing for the automotive and aerospace industries for precision.

NMC Tools

We are a distinguished NMC Tool Supplier with a wide range of NMC Cutting Tools options to operate with efficiency on hard materials, including steels, stainless steels, cast irons, aluminum, superalloys, and hardened steels. The key product line includes

- Endmills: High-performance, vibration- and chatter-free endmills with variable helix and pitch designs, available in 2, 3, 4, 5, and 6 flutes.

- Drills: Duronto Drills for precision hole making, available in various length-to-diameter ratios (3xd to 40xd).

Palbit

Palbit Cutting Tools are cemented carbide and far excel, wear-and temperature-wise, in performance over the classical materials like high-speed steel. Palbit offers a wide range of high-precision tools, including

- Milling: Specialized end mills for materials like aluminum or titanium.

- Turning: implementing embedded special-purpose chipbreakers and tool types, over and above the standard tools, exclusively for machining difficult materials like Inconels.

- Drilling: Maxpro drillings, micro-drilling systems, and detachable investigations have some special features to speak of.

- Threading and boring: These precision threading inserts and boring bars are such that they would give a good surface finish, minimum vibration, and constant measurement.

Finetech

We are renowned as a trustworthy and reliable Cutting Tools Distributor. We partner with Finetech Tooling Systems, which designs carbide tools for precision and constant machining performance and longevity. The tools include

- Micro boring kits: excellent roundness, smooth cutting, and reliability for tiny holes in the aerospace and medical industries.

- Finish Boring Tools: High-precision finish boring tools do the job of generating superior surface finish and precise control over the dimensions. The sturdy but easily adjustable damper vibrations improve the consistency of holes produced and thus yield reliable performances, even under difficult materials.

Advantages of Synergy India Cutting Tools

High-performance cutting tools

As a reliable Cutting Tools Supplier, we provide precision tools with sophisticated geometries, optimized edge preparation, and materials that meet global standards.

Exceptional Durability

Synergy India is recognized as the best Cutting Tools Supplier that uses high-grade carbides, special coatings like TiAlN and AlCrN, and advanced heat treatment methods, making them highly resistant to wear, stable under heat, and tough.

Increased productivity and efficiency

Machining operations faster; diminished tool-change time; reduced vibrations; stable performance in cutting. All these boost productivity, resulting from just this feature.

Steered by Global Engineering

Together with German and other international technology partners, we are able to offer the best tool designs, innovative materials, and advanced machining solutions for the benefit of Indian manufacturers to compete on a global scale.

Economic Processing

Even though these tools are more reliable in the long run, savings will be enormous due to increased tool life and decreased breakage. Factors like improved surface finish and decreased machine downtimes translate to lower cost per component and better margins in the long run.

Functions of Cutting Tools

Cutting tools convert raw materials into final components by removing unnecessary parts from freshly fed machine materials through sharp edges and geometric manipulation.

Advanced tools are designed to provide fine finishes in piles that meet the industry's most stringent standards, thereby reducing the significance of a final finish.

The tools ensure dimensional accuracy, enabling the production of nearly six million identical parts. This issue is highly pronounced in the aerospace and automotive industries, where precision matters are counted in microns.

Cutters themselves have the potential to impede cycle time and prolong the life of machinery, thus lowering power consumption and designing more streamlined and productive manufacturing processes.

How to Choose the Best Cutting Tools?

Different materials demand different tools. Hard metals, soft alloys, composites, and plastics behave differently under machining. Thus, choosing the right grade and coating is vital.

Be it turning, milling, drilling, threading, reaming, or grooving, choosing the correct tool geometry works towards tool life and product quality.

Tools have to withstand heat build-up from the moment they start being used in the machining setup, especially at high-speed operations. Coatings and materials that enhance resistance to thermal wear should be researched.

To prevent breakages and, hence, poor performance, the following must be ensured: the tool should meet the machine's spindle speed, rigidity, and tool-holding systems.

The specialists at Synergy India support manufacturers using the right mix of tools that reduce costs, increase life, and maximize productivity.

Industries we serve

Why Synergy India in Cutting Tools?

Synergy India has been characterized as efficient, durable, and highly effective for all applications in machining. With its high-quality carbide, patented tool designs, and reliable global partnership, Synergy, the leading Industrial Cutting Tools Supplier, helps further industrial development through accelerating production and extending tool life.

- Supportive OEM Partner

- Customized and Application-Specific Solutions

- Strong Technical Expertise

- Consistent and Predictable Tool Performance

- Customer-First Approach

Tell us how can we assist you?

We are always happy to answer any questions!